Planning and Installation

Comprehensive engineering solutions for industrial and commercial applications

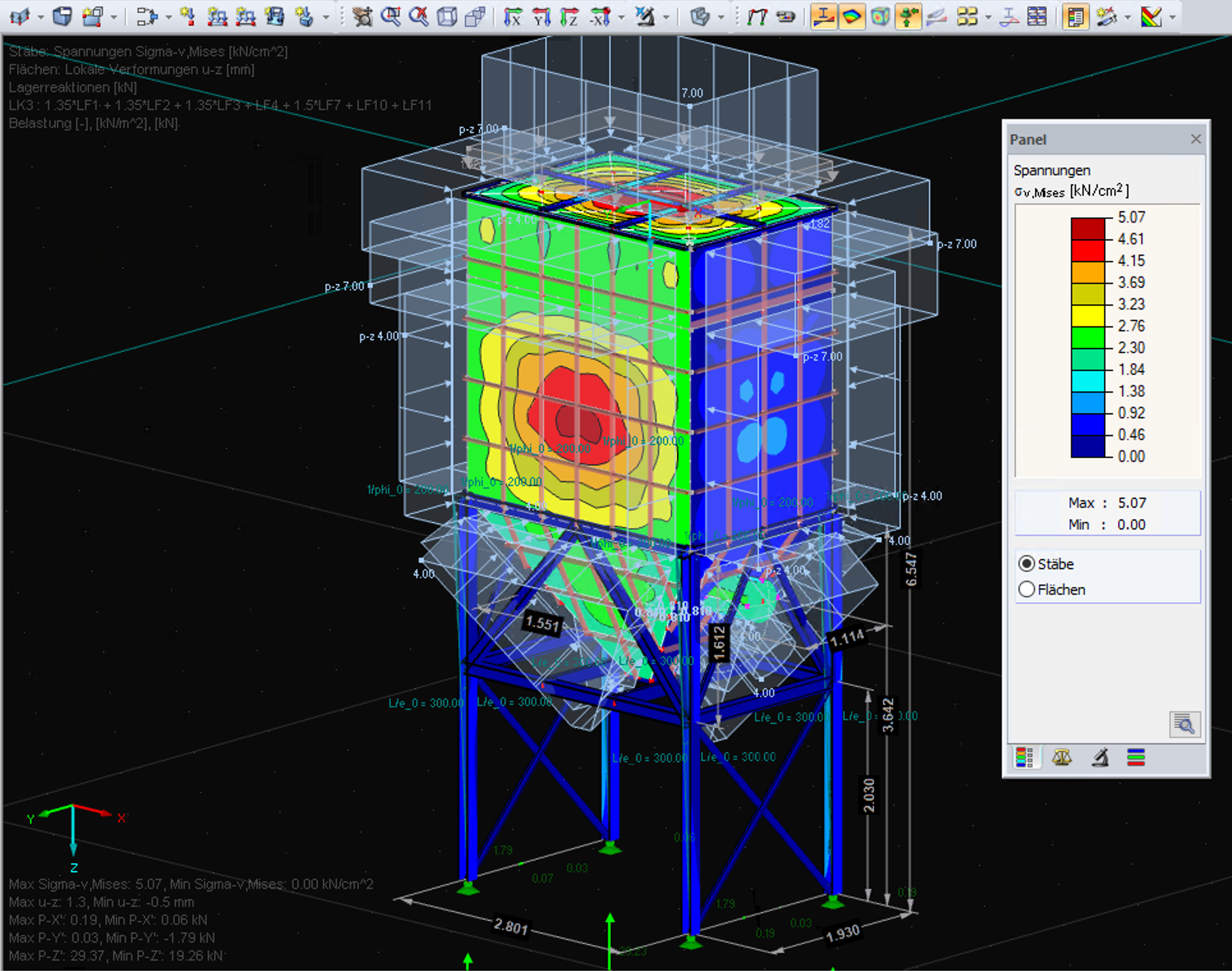

1. 3D Modelling & Layout Design

The process of creating three-dimensional digital representations of physical objects or systems using specialised software. Layout design involves organising these components within a space to ensure functionality, accessibility, safety and efficiency. This is commonly used in architecture, engineering and manufacturing.

Example tools:

2. Detail Engineering

A phase of the engineering process where initial concepts are developed into fully functional, buildable systems. This includes detailed drawings, specifications, bills of materials, load calculations and schedules. It serves as the blueprint for construction, manufacture or implementation.

Includes:

- Structural, mechanical and electrical drawings

- Bill of materials (BOM)

- Technical specifications

- Cost estimates

- Construction planning

3. Equipment and Component Engineering

The design, selection and integration of individual pieces of equipment or components into a larger system. This involves understanding the technical requirements, ensuring compatibility with the overall system and checking compliance with industry standards and safety regulations.

Applications:

- Specification of pumps, valves, motors, heat exchangers, etc.

- Designing customised parts/components

- Evaluating supplier equipment

- Performing failure mode analysis (FMEA)

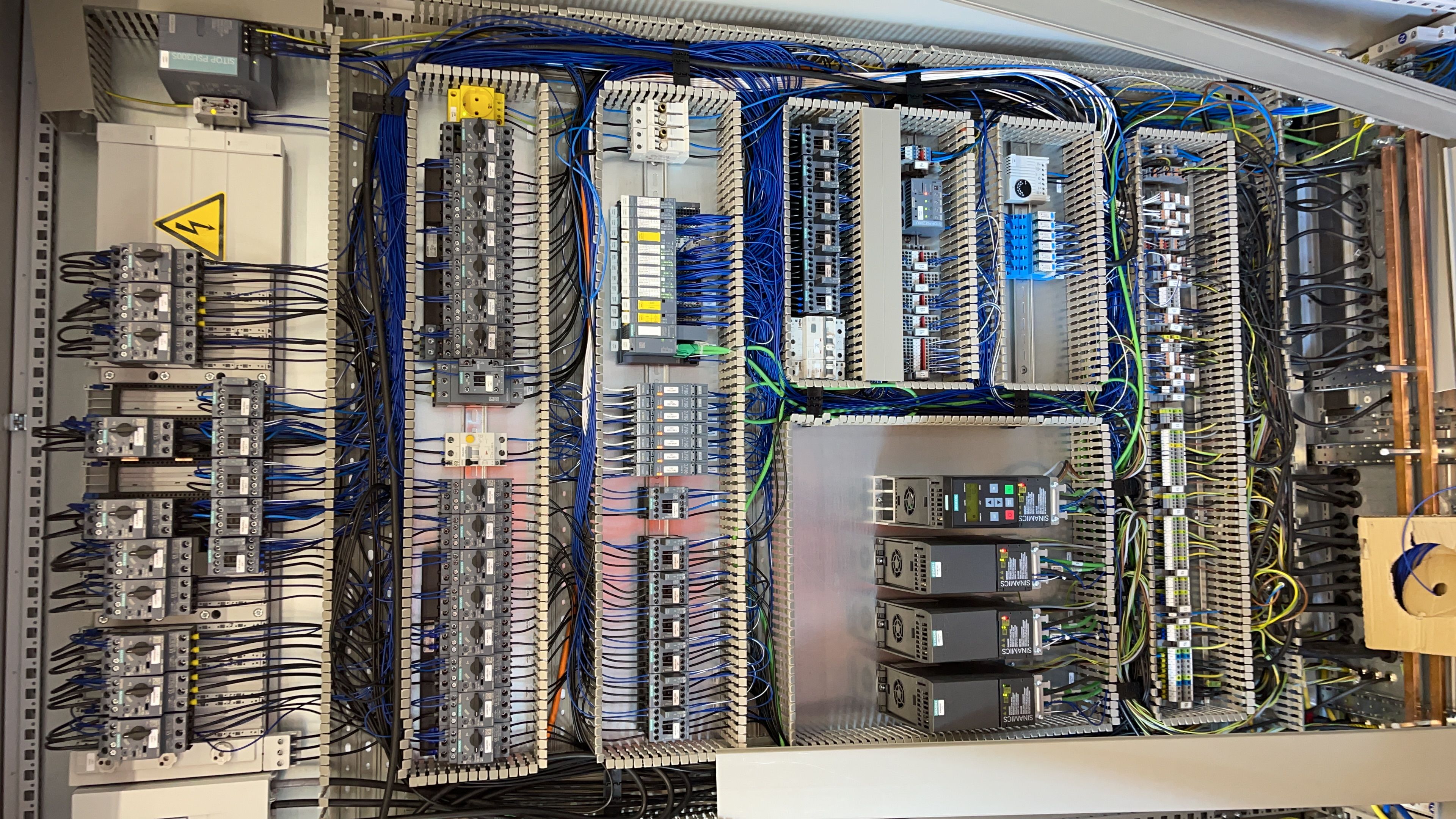

1. Mechanical, Electrical or Automation Installation

The process of physically installing and integrating mechanical systems (e.g. HVAC, pipework), electrical infrastructure (e.g. wiring, panels, lighting) and automation systems (e.g. PLCs, sensors, control systems) into an installation or equipment configuration. It ensures that all systems operate together perfectly in accordance with design and safety regulations.

The scope includes:

- Equipment assembly and alignment

- Electrical cable routing and termination

- Control system integration and sensor configuration

- Compliance with regulations and safety codes

2. Testing and reporting

Complete validation of installed systems and components to ensure that functionality, safety and performance meet specified requirements. Testing is followed by detailed documentation and reports, which are used for quality assurance, regulatory compliance and system approval.

Includes:

- Functional and performance testing

- System calibration and tuning

- Safety and failure tests (e.g. insulation resistance, tightness tests)

- Test reports with results, deviations and recommendations

1. O&M manuals (Operation and Maintenance Manuals)

Comprehensive documents that provide detailed instructions on the operation, maintenance, troubleshooting and safety procedures of equipment or systems. These manuals are essential for end users and maintenance personnel to ensure optimum performance and longevity.

Normally includes:

- Operating procedures

- Routine and preventive maintenance tasks

- Spare parts lists

- Safety protocols and troubleshooting guides

- Manufacturer's documentation

2. Functional process descriptions

Technical documents that explain how a system, process or piece of equipment works. They describe the purpose, sequence of operations, control logic and interactions between system components, and are generally used to guide programming, operations and training.

Used for:

- Defining control system behaviour

- Supporting automation programming (e.g. PLC, SCADA)

- Training operators and engineers

- Aligning system design with functional objectives

3. Development of P&ID (Piping and Instrumentation Diagram)

The creation of detailed schematics illustrating the pipework, instrumentation and control devices in a process system. P&IDs serve as critical reference documents throughout design, construction, commissioning and operations.

Elements include:

- Process flow paths

- Valves, pumps, instruments and control loops

- Tag numbers and line specifications

- Interconnections between mechanical and control systems

1. Electrical and Instrumentation Systems (E&I Systems)

Integrated systems responsible for distributing, controlling and monitoring energy in industrial or commercial installations. Electrical systems supply and manage energy, while instrumentation systems involve sensors and devices that measure and control process variables such as temperature, pressure, flow and level.

Key components:

- Power panels, transformers, cabling

- Field instruments (e.g. transmitters, switches, analysers)

- Control panels and junction boxes

- Signal wiring and loop checks

2. Plant automation

The implementation of control systems (e.g. PLCs, DCS, SCADA) to automate industrial processes, increasing efficiency, consistency, safety and data acquisition. Plant automation replaces or reduces manual intervention, allowing systems to operate autonomously or with minimal input.

Main elements:

- Programmable Logic Controllers (PLC)

- Distributed Control Systems (DCS)

- Human-machine interfaces (HMI) and SCADA systems

- Real-time monitoring and control

- Integration with MES/ERP systems