Continuous Support Services

Comprehensive maintenance and support solutions for industrial systems and equipment

Maintenance and Spare-Parts

On-site inspections and assessments

Comprehensive assessments carried out directly at the facility or workplace to evaluate the condition, performance and compliance of equipment and systems. These inspections help identify risks, maintenance needs and areas for improvement.

Common Activities:

- Visual inspections and functional checks

- Safety and compliance audits

- Condition monitoring and diagnostic tests

- Reports with actionable recommendations

Annual Scheduled Maintenance

Pre-Planning, periodic maintenance of systems and equipment carried out once a year to prevent unexpected failures, extend asset life and maintain performance. This is part of a proactive maintenance strategy.

Includes:

- Inspection, cleaning, lubrication and parts replacement

- System calibration and realignment

- Updating maintenance logs and records

- Coordinated downtime planning

Maintenance Planning and Scheduling

The process of organising, prioritising and scheduling maintenance tasks to ensure timely execution with minimal disruption to operations. Effective planning helps allocate resources efficiently and improves asset reliability.

Common Activities:

- Creating work orders and task lists

- Allocating resources and spare parts

- Coordinating downtime with operations

- Tracking maintenance history and monitoring KPIs

Reliable supply of spare parts

Ensuring the timely availability of critical spare parts to support ongoing operations and minimise equipment downtime. A reliable supply chain is vital for both planned maintenance and emergency repairs.

Involves:

- Inventory management and forecasting

- Supplier coordination and lead time monitoring

- Quality assurance and parts compatibility

- On-site or regional warehousing strategies

Project Management

End-to-end project scheduling

Comprehensive planning and management of all project phases, from inception to completion. It involves developing and monitoring schedules that align with project milestones, resource availability and client deadlines.

Key Components:

- Developing the Work Breakdown Structure (WBS)

- Gantt charts and critical path analysis

- Resource levelling and allocation

- Schedule follow-up and updates

Contract & Site Management

Oversee contractual obligations and day-to-day site operations to ensure compliance, efficiency and safety. This includes subcontractor management, cost control and problem resolution during project execution.

Responsibilities include:

- Contract negotiation and execution

- Logistics and site coordination

- Health, Safety and Environment (HSE) compliance

- Communication of progress and stakeholders

Supervision of Execution and Commissioning

Supervision of installation, system integration and commissioning activities to ensure that the systems function in accordance with the project and customer requirements. This phase ensures a safe and successful handover to operations.

Involves:

- Supervision of mechanical, electrical and control installations

- Functional testing and pre-commissioning

- System start-up and tuning

- Final performance verification and customer acceptance

Review and Updates

Documentation

Preparation and delivery of clear, precise and organised technical documents that support the design, operation, maintenance and regulatory compliance of systems and projects. Documentation ensures traceability, consistency and knowledge transfer.

Typical results:

- As-built drawings and schematics

- Technical data sheets and wiring diagrams

- Test and certification records

- User manuals and download packs

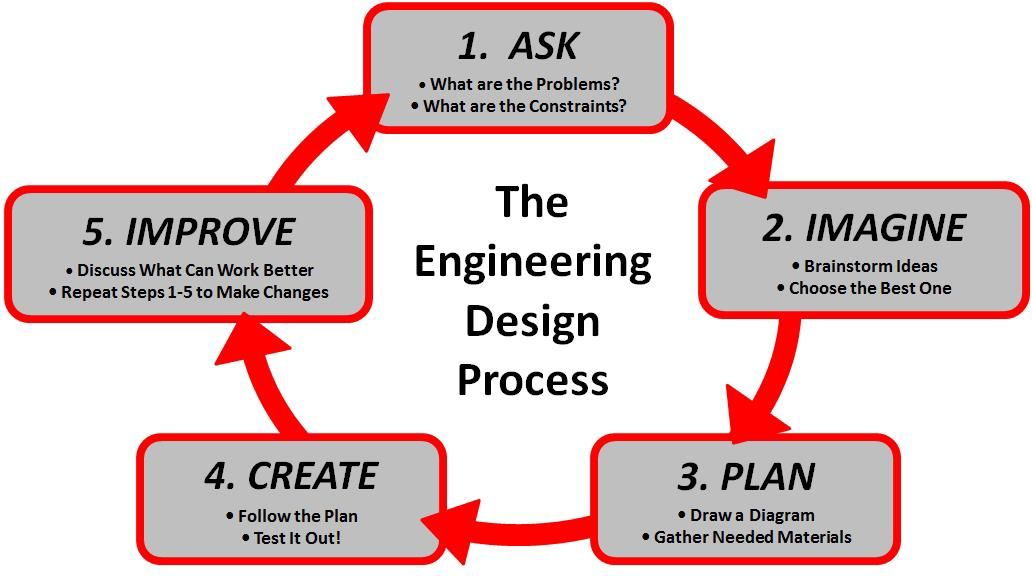

Review and expansion of plant functionality

Evaluation of existing plant systems to assess current performance, identify bottlenecks and develop strategies for upgrades or expansions. This service supports plant optimisation, capacity increase and adaptation to new processes or technologies.

Scope includes:

- Performance diagnostics and root cause analysis

- Capacity studies and preparation for the future

- Integration of new systems or technologies

- Compliance with updated regulations or industry standards

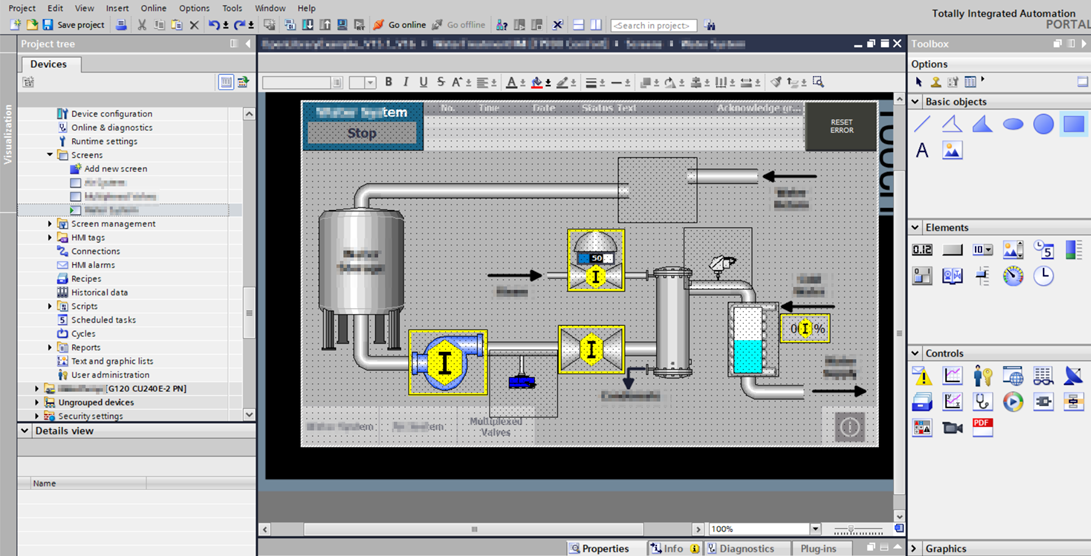

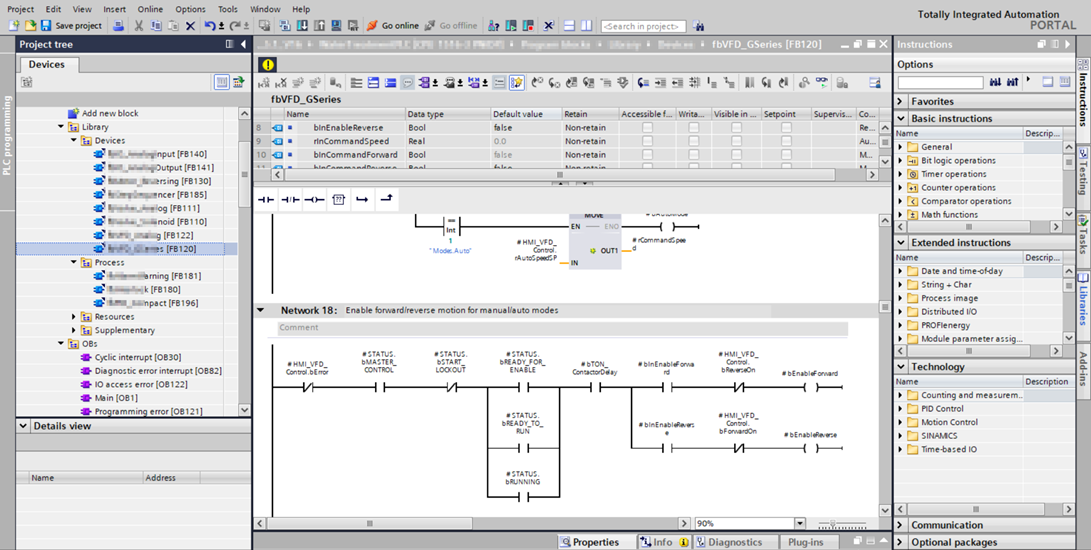

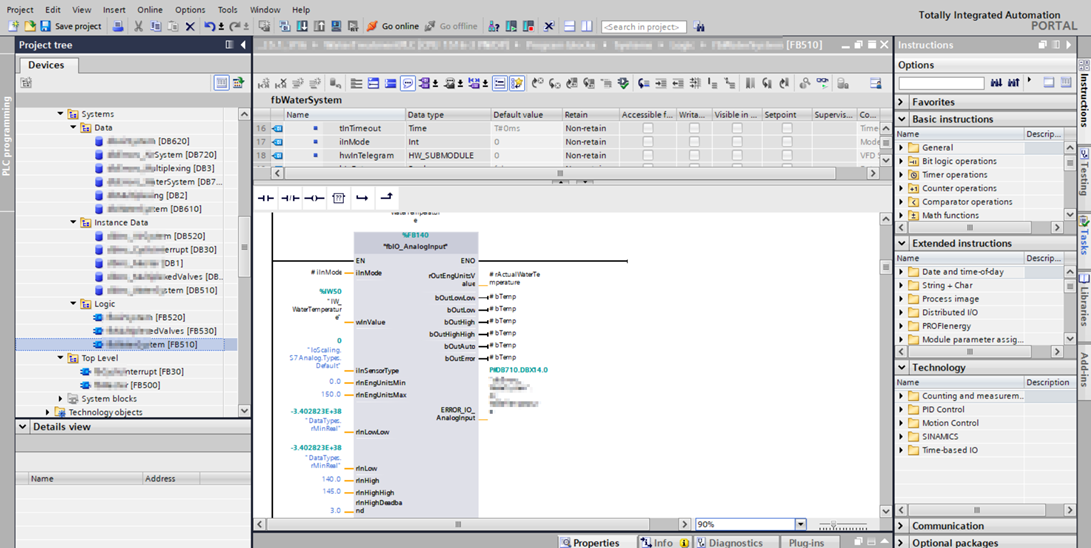

Automation and Electrical Systems

Design, development, integration and support of the electrical and control infrastructure that drives plant or facility operations. These systems form the backbone of process automation, safety interlocks and power distribution.

Services may include:

- PLC and HMI programming

- Electrical system design and panel manufacture

- Power and control wiring

- Network communication and remote monitoring integration

Service Delivery

Remote access to the site to resolve minor problems

Use of secure remote connectivity to access plant systems for diagnostics, troubleshooting and minor corrections without the need for physical presence. This enables faster response times and reduced downtime.

Features may include:

- Remote PLC/HMI diagnostics

- Minor adjustments to control logic

- Alarm and event monitoring

- Remote support via VPN or industrial remote access tools

Regular site visits

Scheduled face-to-face site visits to provide ongoing support, maintenance supervision, system checks or operator assistance. These visits ensure that systems remain reliable, efficient and well supported over time.

Visit objectives may include:

- Routine system health checks

- Operator training and updating

- Practical troubleshooting

- Follow-up on recent updates or modifications

Implementation of Plant Improvements

Execution of improvement projects with the aim of increasing the efficiency, reliability, safety or capacity of existing plant operations. These improvements are based on performance evaluations, customer feedback or changes in production needs.

Examples of improvements:

- Updating obsolete control systems

- Adding automation or process optimisation features

- Improving energy efficiency or safety systems

- Reconfiguring layouts for operational flow